Introduction

Phase Dynamics PPM Water-Cut Analyzer raises the standard in innovation. The PPM Analyzers are highly sensitive real-time instruments developed specifically for use in the oil industry to measure parts per million moisture levels in hydrocarbon liquid.

Typical applications requiring ppm measurement capability include:

- Water in condensate monitoring prior to injection into a subsea pipeline

- Moisture levels in NGL for gas processing plants

- Moisture detection in heat transfer fluids such as glycols and Dowtherm

- Moisture detection in cryogenic applications

The product line is based on the innovative sensing technology of oscillator load-pull. As the mixture of flowing liquids passes through the measurement section, the oscillator senses the entire cross section of the material and instantaneously shifts in frequency as the material composition changes. This frequency shift is a direct measure of flowing material change within the measurement section.

The product family is customizable to meet the exact needs of the global market. The typical system includes the Measurement Section, an Electronics Enclosure, a Coriolis flow meter, a molecular sieve, interconnecting valves, tubes, and system cables.

PPM Analyzer System

Measuring Range

The Analyzer measurement range is listed in the table. Uncertainty is expressed as a two standard deviation confidence interval.

|

Parameter

|

Range

|

|

Measuring Range

|

0ppm to 1,000ppm

|

|

Uncertainty (2σ)

|

+/-20ppm

|

|

Repeatability

|

+/-10ppm

|

|

Resolution

|

1ppm |

Certifications

This family of Analyzers are available with the following certifications:

- CSA: Class1, Division 1, Groups C and D; Class1, Zone 1, Group IIB

- FM: Class 1, Division 1, Groups C and D

- ATEX: EEx d IIB T5, CE Ex II 2 GD, IP66

- PED: Module A1

Reports

In addition to the certifications, several additional reports are available.

- PMI - Positive Material Identification

- NDE / NDT - Non Destructive Examination / Testing

Workmanship Standards

Workmanship and material standards include these items:

- ASME Section IX

- ASME B 31.3

- EN 10204

- NACE Standard MR0175/ISO15156

- ISO9001:2015

Temperature

The Measurement Section is the portion of the Analyzer that contains the sensing elements where fluids are flowing at process conditions. Process temperature capabilities are 0 to 104ºC.

The Electronics Enclosure Section contains the majority of the electronics with displays and user I/O. Ambient temperature capability is -40ºC to +60ºC.

Measurement Section

The Measurement Section is configured in a "Z" configuration with 1/2 inch Swagelok tubing fittings. Standard material is 316/316L stainless steel with other options available. Maximum operating pressure is 3,000 PSI. Process temperature is monitored with a built-in RTD sensor. A flow rate of 3 to 7 liters per minute is suggested. Pressure drop across the measurement section is less than 10 PSI.

Electronics Enclosure Section

The Electronics Enclosure is available in explosion proof models made from either stainless steel or aluminum.

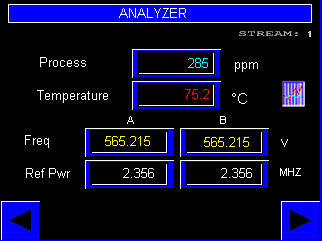

The display is a 6-inch color touchscreen with a data logging feature. Graphing functions are provided to present trend data in an intuitive easily discernable format. The enclosures provide for user interaction through a 4-button interface in addition to the touchscreen.

Touchscreen Display

System power is supplied through either 100 to 240 Vac or 24 Vdc. Typical power dissipation is 18 Watts, maximum power dissipation is 33 Watts.

The data interface includes MODBUS, HART, analog I/O, pulse input, and alarm relays.

The Enhanced Electronics package option includes:

- 4 x MODBUS RTU

- 1 x HART (opt.)

- 1 x 4-20mA input

- 1 x 4-20mA output

- 1 x pulse input

- 2 x alarm relays, 1A / 125Vac

The Expanded Electronics package option includes:

- 4 x MODBUS RTU

- 1 x HART (opt.)

- 5 x 4-20mA input

- 5 x 4-20mA output

- 3 x pulse input

- 2 x alarm relays, 1A / 125Vac

Density and Flow parameters are available for display and output through the data interface ports.

Documents

Request for Price Quotation

Price quotations for the PPM are based on the information provided in the Application Submission Sheet.

- Application Submission Sheet - Please fill-in this form and email to This email address is being protected from spambots. You need JavaScript enabled to view it.